To fully understand how to install a high-velocity HVAC system, one must know what it is and what it does. Basically, it is a small duct, high-velocity airflow, heating and cooling system designed to fit in structures that have space constraints or architectural limitations or requirements. Many home designers choose such a system because they do not have to design a unique structure to hide the heating and cooling system components.

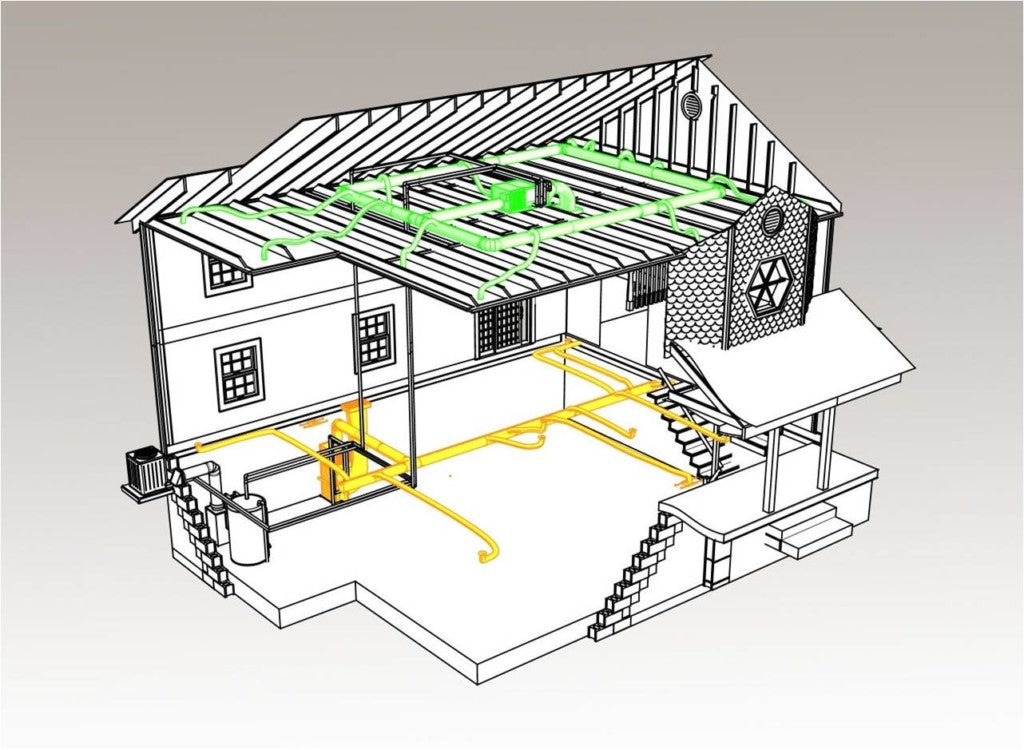

The high-velocity system distributes conditioned air by means of flexible, pre-insulated, 2-inch inside diameter tubing, which is fed through wall structures and around obstructions. The system uses sound attenuation materials that absorb airborne and regenerated noise and provide a quiet comfort system.

The heart of the system is a single cabinet blower and coil air handler that is designed to fit in tight spaces while providing efficient cooling and heating from its refrigeration coil.

The 10 steps to a successful installation are:

1. Calculate The Load

The first step is to do a load calculation. SpacePak provides a "Kwik Way" sizing form that is designed to accurately provide a room-by-room load for the high-velocity system. Also offered is an "Informer" CD including calculation software. The software can be downloaded at no cost at www.spacepak.com.

Now that the system has been properly sized for the structure, we can begin our equipment installation.

2. Find A Suitable Location For The Fan Coil Unit

The initial consideration is the location of the fan coil unit. The fan coil unit may be located in an unconditioned space. Areas such as an attic, garage, or crawl space are acceptable as long as the location is protected from the weather and local codes are met. The fan coil unit may also be located in a conditioned space such as a basement, closet, or utility room. Two types of fan coil configuration are offered - horizontal and vertical cabinets.

One must also consider the location of the return air filter box and duct. Another important consideration is the location of the 9-inch inside diameter plenum, air supply tubing, refrigerant lines, and condensate drain line.

When installing a fan coil unit in an attic space, such as above a ceiling, it is recommended to install a secondary drain pan and/or a float switch. Again check your local codes for this requirement.

The unit may be installed on a platform or suspended from a pre-assembled suspended platform. The platform (fixed or suspended) must be close enough to the selected return air box opening for ease of connecting the return air plenum duct (see below for platform instructions).

3. Cut The Return Air Opening

Next, cut the return air opening. Select your exact location for the return air duct. Avoid installing the return air box in a dining room, living room, or kitchen unless the air duct can be installed with a 180-degree bend. Once the opening is cut based on the size and dimensions of the return air opening, the fan coil may be passed through the opening.

The return air box is designed to fit between joists that are 16 inches on center with a 14-inch width. For wall applications such as when using a vertical free-standing fan coil unit, be sure the opening will allow for a 90-degree bend in the return air duct. Next check for proper fit of your return air box. However, do not install the return air box until your installation is complete because you may want to pass materials for your installation through this opening.

4. Construct A Simple Platform

You can construct a simple platform based on the size of the fan coil unit. (Instructions for this may be found in the installation manual). It is recommended to use 2- by 8-inch stud lumber and a minimum of 1/2-inch plywood for platform construction. Always use the provided isolation strips under the unit for best performance.

For locations where the fan coil unit must be suspended, suspend the platform overhead by 1/4-inch threaded rods. Never connect a threaded rod directly to the fan coil cabinet. It's not necessary to secure the fan coil unit to the platform because the weight of the unit will hold it in position. Remember to leave room for servicing.

5. Attach Supply Plenum Ring

Remember that the supply plenum ring will be several inches lower than the bottom of the fan coil unit. It will be necessary to move the fan coil past the platform edge to accommodate the plenum ring. The plenum ring attaches to a square opening with four screws provided. In addition, be sure to attach the plenum ring gasket to the fan coil cabinet before mounting the supply plenum ring.

6. Connect The Condensate Drain

You are now ready to connect the condensate drain trap (supplied) to the fan coil unit. Refer to the instructions with the supplied condensate drain trap. Always run the condensate drain line from the trap to a suitable drain in accordance with local codes. Be sure that the drain line is pitched 1/4 inch per foot. Never connect the condensate line to a closed drain system. Always use a secondary drain pan for overhead systems.

7. Connect Refrigerant Lines

Connect the refrigerant lines from the outdoor condensing unit to the indoor fan coil unit. Always follow the condensing unit (outdoor unit) manufacturer's instructions for installing, sizing, trapping, charging, and using filter-dryers.

8. Connect Supply Tubing And Plenum Duct

When installing the air distribution components, it is always a good idea to do a system layout based on your sizing parameters. The plenum duct may be run in practically any location that is accessible for the attachment of the supply tubing. (Review suggested layouts in the installation manual).

Plenum duct installation, all tees, elbows, and branch runs must be a minimum of 18 inches from the fan coil unit and any other tee, elbow ,or branch supply run. It is recommended that you keep the use of tees and elbows to a minimum to keep the system pressure drop to a minimum. The plenum duct comes in 6-foot lengths and may be cut to desired lengths depending on your system layout.

When installing the plenum to the unit, it is recommended you cut off the male end of the first section. Then insert the plenum duct section into the receiving collar on the fan coil unit. Be sure to push the duct in tight to form a snug joint. Then flatten the sheet metal tabs against the plenum duct and insert the flat head pins. Next, wrap and tape in place the 6-inch-wide piece of foil face insulation over the taped joint. Be sure the insulation is pushed up against the fan coil unit.

Continue to assemble the plenum duct making sure the "shiplap" joints are snug and taped securely. (SpacePak recommends Polyken #222 tape or equivalent). Once your plenum duct has been installed, the plenum end cap will now go on the end of your plenum run. The plenum end cap contains an insulated cushion that is pushed up tight against the duct end. Hold the end cap firmly in place, then insert the flat head pins through the sheet metal tabs at the end of the cap. Cross-tape the end cap securely with a circumferential wrap around the end cap. It's always a good idea to strap or cradle the plenum to avoid plenum movement during operation, which could cause joints to come loose.

9. Install Terminator Outlets And Sound Attenuation Tubing

You are now ready to begin installation of the room terminators/outlets and the sound attenuation tubing. (Room terminators and sound attenuating tubing are provided in the installation kits.) Mark the locations where you would like to install the room terminators. When marking the location for the room terminator, the center of the terminator should be 5 inches from a wall edge. When installed in a room-ceiling corner, the location should be 5 inches from each wall edge. After you mark the location, drill a 1/8-inch hole for the outlet. Allow at least 2 inches of clearance all around the 1/8-inch hole. After all clearances have been checked, use a 4-inch hole saw to cut a hole, using the 1/8-inch hole as your pilot.

Next assemble the room terminator to the sound attenuating tubing by fitting the connectors together and twisting until tight. If the terminator is being installed in a floor location, you must fabricate a small 1/4- by 1-1/2-inch-square screen and place the screen between the terminator faceplate and the tubing connector. Then push the free end of the sound attenuating tubing through the 4-inch hole until the toggles on the terminator snap into place. Center the two spring clips on a line parallel to the direction of the tubing so the faceplate doesn't pull away from the ceiling.

10. Install Supply Tubing

You are now ready to install the supply tubing. (Quick connectors, plenum takeoffs with gaskets, and balancing orifices are supplied with the installation kit.) Always avoid sharp bends in the supply tubing and attenuator tubing. Supply tubing typically comes in 100-foot lengths and may be cut to desired length. The minimum length is 6 feet and the maximum is 30 feet with attenuator. Cut your supply tubing to the proper length. Then install the connector to the tubing by threading it into the cut end of the tubing. Tuck the insulation and Mylar scrim under the collar of the connector. Wrap tape around the connector to secure the two pieces together.

Finally, install the connectors together by using a twist action until they are secured.

At the plenum location you have selected, cut a 2-inch hole in the plenum with the hole cutter supplied. Be sure that your hole is at a 20-degree down angle to eliminate a strain on the plenum. To cut the hole with the hole cutter, rotate the cutter back and forth, applying just enough pressure to force the serrated edge into the foil and insulation of the plenum. Remove the hole cut out from the plenum. Be sure there is no flap left that could block the hole during operation.

Next, place the plenum takeoff gasket around the hole. Then place the plenum takeoff connector into the hole in the plenum. Orient the plenum takeoff to match the curvature of the plenum duct. Insert the plenum fasteners by hand one at a time. Using pliers, snap the fasteners into place. Once the plenum takeoff is in place, you're ready to install balancing orifices if necessary. Next, install a connector into the remaining open end of the supply tubing following the same procedure as before. Then connect the connector from the tubing to the plenum takeoff following the twisting action used to connect the connectors. You have now completed your supply run.

Once you have completed your supply run installations, you can begin to install your return air duct and return air box. Remove the return air grille and filter from the return air box assembly. Insert the return air box into the return air opening you cut earlier and fasten the frame with four screws through the holes provided on the long side of the box. Then, insert the return air grille into the box and fasten with the four screws provided. Open the grille and insert the filter. Then connect each end of the return air flexible duct to the elliptical end of the fan coil and the return air box connections with the clamp bands.

Electrical Connections

All electrical installations must conform to the requirements of the local authority having jurisdiction or in the absence of such requirements refer to the National Electric Code ANS/NFPA No. 70 latest edition and any additional state requirements. Locate the room thermostat on a wall near the return air box about 48 inches from the floor. Connect the low voltage thermostat wiring to the low voltage control block in the unit. Refer to the wiring diagram for the unit in the installation manual. The fan coil unit must be connected to a separate circuit using a 15-Amp fuse and 14-gauge wire. The electrical service requirement is 208/230/60/1 power supply.

Source: https://www.achrnews.com/articles/103218-ten-steps-to-installing-a-high-velocity-hvac-system-1